VM V-Cone®: When is a Differential Pressure Meter Best for Municipal Applications?

Oftentimes in municipal flow applications utilities and districts opt for a propeller meter, an electromagnetic (mag) meter, or another type of “no moving parts” meter like an ultrasonic device.

However, there are instances in which a differential pressure (DP) meter is a more attractive option, and specifically the VM V-Cone, McCrometer’s DP meter designed for a wide variety of municipal flow applications.

VM V-Cone: Convenience in Low Maintenance

Shutting down a water district’s pipeline for routine maintenance or repairs is a major hassle, and a costly one at that, when cutting off a literal revenue stream. Many popular municipal flow measurement devices require intermittent cleaning, especially if the media flowing contains a harsh chemical or causes corrosion or buildup.

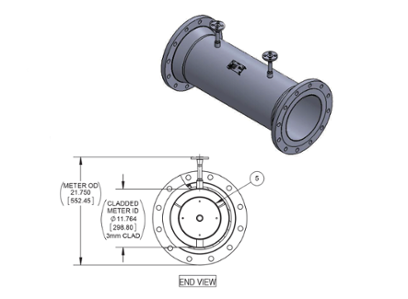

In one instance, a VM V-Cone was the desired retrofit meter to replace a venturi meter that had grown shut over time due to scaling inside the pipeline and the meter itself (Figure 1). Whereas other meters have limitations to what material they can be engineered from, the VM V-Cone can be customized from durable materials that withstand whatever flow runs through it. This factor contributes to the meter’s 25+ year lifespan and the need for virtually zero maintenance, which means that water utility operators can meter with confidence knowing their VM V-Cone is always optimally performing.

Figure 1: A venturi meter with severe scaling, preventing an accurate read on flow and requiring consistent maintenance. Photo courtesy of McCrometer.

Itty Bitty Real Estate

Ideal for new projects as well as retrofits, the VM V-Cone is often chosen for its extremely low straight run requirements and self-conditioning technology. Many older water districts simply don’t have the real estate or the capital to add additional piping to suit the straight pipe-run requirements of flow meters that cannot handle a variety of flow disturbances.

Elbows? No problem. T and Y junctions? Won’t stop the VM V-Cone!

The VM V-Cone requires close to zero upstream and downstream straight run, while still maintaining better than ±1% accuracy. These specs make the VM V-Cone a solid choice for applications such as well sites, pumping stations, filter galleries, pressure relief vaults, pits, manholes, and general distribution lines.

V-Cone vs. VM V-Cone: What’s the Difference?

Invented by McCrometer in 1985, the V-Cone typically measures flow for a variety of industries, most notably oil and gas and industrial. The VM V-Cone, on the other hand, is specifically designed to meet the needs of municipal applications. Coated in McCrometer’s proprietary fusion-bonded epoxy coating, the VM V-Cone has a lifetime guarantee against delamination and liner tearing. In addition, the VM V-Cone is a plug-and-play system that is composed of the V-Cone element, transmitter, and isolation manifold, making it easy to install and start getting the flow data needed to make informed decisions about water operations.

Specific applications where water velocity is slow may pose a challenge to the VM V-Cone, as its turndown ratio is lower compared to the V-Cone, or even a mag meter. However, if the flow is strong, accuracy is key, and real estate is tricky, the VM V-Cone is the investment meter that will consistently bring value to water operations professionals for years to come.

Related Posts

Featured Posts

Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This...

Produced Water and Blending Flow Meter Use Case

Produced Water is a byproduct of oil production. Whether it is a byproduct of flow back or the water component of the oil separation process, produced water can be a difficult measurement point but is a very important part of the process. Several parameters make it...

Get your Groove on Now: McCrometer’s Grooved-End Mag Meter Now Available

It is time to get your Groove On. McCrometer has released their innovative Electromagnetic Flow Meter with integrated Grooved End connections. Are you tired of bolting on extra flanges with Victaulic end connections welded to them? It is time consuming and makes an...

Request More Information