-

PRODUCTS

-

Differential Pressure Flow Meters V-Cone

VM V-Cone

Wafer Cone

Exact Steam

Connected Solutions FlowConnect

McCrometer Connect

Smart Output

SmartTrax

Electromagnetic Flow Meters FPI Mag

MCMAG 2000

MCMAG 3000

SPI Mag

ULTRA Mag

Dura Mag

Oil & Gas Series Field Mag 3000

Field Mag 5000

Electromagnetic Flow Meter Electronics ProComm

ProComm GO

Propeller Flow Meters FS100 Flow Straightener

FS200 Flow Straightener

McPropeller

Water Specialties.

-

Differential Pressure Flow Meters V-Cone

- INDUSTRIES

- RESOURCES

- BLOG

- SUPPORT

Seal The Deal: Shielding Against A Mag Meter's Achilles Heel

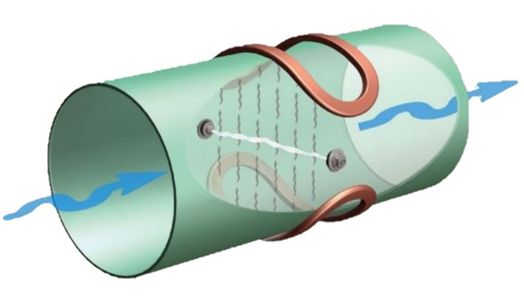

When it comes to metering water flow — drinking water or wastewater — full-bore mag meters offer many advantages. While the underlying technology based on Faraday’s Law of electromagnetic induction (Figure 1) is shared among all styles of full-bore mag meters, specific implementations have impacts on longevity and accuracy. Here is what to look for when the time to choose arrives.

Built For The Water Environment

With sensing focused on the full cross-section of the pipeline, full-bore mag meters offer reliable, accurate performance while being relatively tolerant of disturbances in the flow. With no moving parts and high accuracy, they are often chosen to replace mechanical meters such as propeller meters.

Mag meters typically tolerate turbulence from elbows or Ts located within one or two pipe diameters (1d to 2d) upstream and zero to 1d downstream. Chemical injection ports or valves might cause turbulence requiring 2d of straight pipe upstream of the mag meter. Depending on meter features and cost, accuracy can range from + 1 percent to + 0.5 percent of the standard operating range. Operation is typically reliable over a long service life, although some regulated applications might still mandate periodic calibration, usually every one or two years.

The one Achilles heel can be the protective layer between the metallic body and the conductive liquid flowing through it that insulates the meter against short-circuiting. Where separately installed liner inserts are used to provide that protection, deterioration of those liners can be one of the biggest complaints about full-bore mag meter performance in water industry applications.

Mag Meter Liners vs. Coatings

The most durable mag meter coating is one that is not simply layered on the inside of the tube, but one that completely envelops the entire assembly with thermoset powder coating epoxy. This epoxy bonding process provides 100 percent continuous coverage, enveloping the entire interior and exterior surface of the mag meter housing with uninterrupted protection. It provides excellent adhesion to resist corrosive soils, hydrocarbons, harsh chemicals, and even sea water and to avoid problems experienced with other types of interior “sleeve” linings, which can delaminate, separate, or collapse.

This type of coating has demonstrated its durability in the field by standing up to flows that include sand, rust, or harsh chemicals in the water — without cracking, peeling, or falling off. If those problems occur, particles of the liner can get into the process flow and the mag meters can produce grossly inaccurate readings.

The chemical compatibility for this NSF-61-approved dry-powder epoxy coating is extensive, exceeding most conditions typically experienced in water or wastewater treatment plants (Figure 2).

Common Capabilities, Different Options

Full-bore mag meters with durable full-coverage epoxy coatings are available in several feature sets to meet different requirement levels, including options for visual readings at the meter or for remote reading and the ability to tolerate sand- or clay-laden well-water without liner damage.

- Low-Cost Alternatives. Mag meters with + 1-percent accuracy are often used as replacements for mechanical meters in non-billable water and wastewater applications. They provide a good alternative for simple meter reading and data logging capabilities where mechanical meter accuracy begins to wane as a result of wear. Applications range from district meter area (DMA) monitoring in drinking water distribution systems, to metering clean wastewater effluent for reuse in irrigation or industrial use, to dewatering applications in construction applications. These affordable meters offer:

- A more accurate alternative to mechanical meters.

- Ability to read usage rate and totalizer visually, on the spot, or to convert output to a 4-20 mA signal, or to connect to an independent telemetry system that will transmit readings remotely.

- Battery-powered remote operating capability with five-year guaranteed battery life, as proven in agricultural/irrigation applications where line power is typically not available. An optional 10-32 VDC power port is also available.

- Lifetime warranty on the continuous coating protecting the interior and exterior of the meter body.

- Compatibility with Sensus and Itron 3-wire communication protocols.

- IP67 rating for outdoor installation.

- Full-Featured Performance. These fully empowered mag meters provide + 0.5-percent accuracy that can more than pay for themselves in billable-water applications. These can include bulk transfer metering between two drinking water distribution utilities, tracking water being reused for irrigation or industrial use, identifying water loss in times of scarcity, etc. Full-featured meters also provide the same accuracy for non-billable internal applications such as DMA monitoring or documenting clean wastewater discharge. They also offer:

- Accurate in-plant flow monitoring for calculating appropriate chemical treatment additions.

- Lifetime warranty on the continuous coating protecting the interior and exterior of the meter body.

- Custom lay lengths manufactured to the exact size required for retrofit installations avoid accuracy compromises introduced by unnecessary spool pieces.

- Signal converter display that can be meter mounted for instant reading or remote mounted via cable connection up to 500 feet away.

- IP68 rating with fully potted electronics for outdoor installation in underground vaults.

- HART, Profibus, Modbus, Sensus, and Itron communication compatibility.

Consider Support Services, Too

Aside from sensing accuracy, variability in the water conveyed, and interior coating protection, there are other service factors to consider when evaluating mag meters for water industry applications.

Onsite customer service — when appropriate — can make the difference between instant problem resolution and an expensive shutdown to remove, replace, and return a meter for factory diagnostics or repair. One example of such an occurrence could be dealing with electronic interference in the plant environment that impacts meter reading accuracy. Another could include assistance in designing and sizing replacement mag meters to fit the specific space and configuration in an existing installation.