-

PRODUCTS

-

Differential Pressure Flow Meters V-Cone

VM V-Cone

Wafer Cone

Exact Steam

Connected Solutions FlowConnect

McCrometer Connect

Smart Output

SmartTrax

Electromagnetic Flow Meters FPI Mag

MCMAG 2000

MCMAG 3000

SPI Mag

ULTRA Mag

Dura Mag

Oil & Gas Series Field Mag 3000

Field Mag 5000

Electromagnetic Flow Meter Electronics ProComm

ProComm GO

Propeller Flow Meters FS100 Flow Straightener

FS200 Flow Straightener

McPropeller

Water Specialties.

-

Differential Pressure Flow Meters V-Cone

- INDUSTRIES

- RESOURCES

- BLOG

- SUPPORT

Case Study: Ashley Valley Water & Sewer Improvement District Relies On FPI Mag Flow Meter To Comply With Allocation Quota

By John Callison, Technical Staff, McCrometer

and Michael Charnholm, Application Engineer, Goble Sampson Associates

Click here for a printable PDF version.

Overview

Ashley Valley Water & Sewer Improvement District (AVWSID) serves rural county residents who live outside the city of Vernal, Utah. The water district supports a growing population of 10,000 people, as well as local ranchers and farmers who raise livestock, alfalfa, hay, various grains and feed corn.

The district’s water supply is derived from a year-round active spring additionally fed by mountain snow melt. Seasonal and weather variations can affect the output of this vital resource which the district shares with several other water entities. Accurate tracking of water use for allocation and conservation purposes is therefore extremely important for AVWSID.

The district’s drinking water plant is an up-flow clarifier, which according to its water allocation, can process eight million gallons (mgd) a day of raw water.

If the plant exceeds its water share allocation, then the district would be forced to purchase water at a more expensive rate, which affects operational costs and customer rates.

Ryan Goodrich, Assistant Manager, AVWSID, said, “We installed the McCrometer FPI Mag® flow meter in our raw water line where it comes into our treatment plant. Accurate entry point of measurement is critical for us so we know how much water we treat, use internally and supply each day. We compare the daily flow data to our actual water right share.”

Goodrich said, “The FPI Mag magflow meter is performing very well in normal operations, including high flow cycles, such as when we flush the plant’s filters. The immediate benefit of the FPI meter is its accuracy and reliability over the full range of flow rates required by our plant’s operations.”

The CWTF was originally built in 2002 and became operational in 2004. During construction, CH2M Hill selected a fiberglass electromagnetic insertion style flow meter to support its UV disinfection system. The meter was chosen for its ease of installation, small profile, low maintenance and cost saving features. This fiberglass mag meter became a part of McCrometer’s flow product line when the manufacturer was purchased several years later.

CH2M Hill’s subsequent experience with McCrometer demonstrates how operators and suppliers working together with evolving technologies can achieve advances that benefit the entire water industry. In this particular case, coordination and communication between CH2M Hill and McCrometer helped in the new design of the current FPI Mag flow meter.

John Wesely, CH2M Hill’s CWTF operations manager said, “The original fiberglass meters weren’t installed as the primary plant flow meters, but given the more favorable hydraulic conditions in the UV reactor pipelines, they turned out to be the most accurate in the facility. When we decided to install the redesigned FPI Mag® flow meters, we planned to use them as the primary meters to measure treated water for compliance purposes and to determine chemical and power efficiencies.”

“We combine the flow of the 13 FPI Mag meters on the UV disinfection lines to calculate total treated plant flow each day. While we have flow meters in other locations that were intended to measure totalized plant flow, our experience has shown the FPI Mag meters provide the most accurate and reliable measurement of plant totalized flow each day.”

The Problem

With the need to replace an existing flow meter for improved performance, the AVWSID plant operations team was looking for the most reliable flow measurement solution that also would be the easiest to install without

impacting operations. They wanted to minimize operational interruptions and avoid the need for extra personnel to bring the flow meter into service. For this pilot plant application, they were looking for a high-performance, easy-toinstall, economical flow meter, with minimal maintenance requirements.

The Solution

The district staff contacted the applications team at McCrometer who recommended the FPI Mag flow meter due to its consistent, highly accurate performance, easy hot tap installation, low maintenance and versatility.

The installation process at the point of entry to the plant was simple: The 18 inch main line pipe was tapped and an FPI Mag meter with a saddle mount and transmitter was installed. Since the previous meter had already been wired, it was easy to connect the transmitter.

Goodrich said, “We deal with many different types of meters and applications where the meter display needs to be calibrated, which takes extra time and can be confusing. I’m pleased that we could install the FPI Mag so quickly, and the display right away made it easy to see it was working.”

According to Goodrich, adding the meter to the plant SCADA system was simple. He said, “The instructions were clear. As soon as the connection was made, the meter showed up immediately on the SCADA system.”

The district staff made a few adjustments to its SCADA program, and the meter was fully operational within the system. With no programming necessary, there was no need to hire a programmer and spend extra money to bring the meter online. Goodrich said, “That extra cost for programming can be a real problem in some cases and will actually prevent us from using some meters.”

The FPI Mag meter has been installed at the plant for about seven months with no maintenance needs. Goodrich said, “The meter design appears to be as if there will be no issues and it is simple to pull and clean when necessary.”

Goodrich noted there was a burst pipe incident at the plant, which soaked the instruments and automation equipment. The staff had to turn off the power to fix the problem. When the power was turned back on, the FPI Mag meter and its transmitter came right back online without the need to reset parameters or make additional adjustments.

The Technology

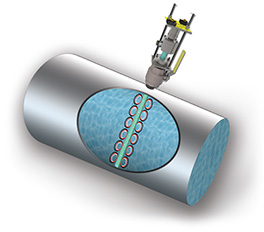

With AVWSID’s critical need for accurate measurement to ensure compliance with its water right share, the FPI Mag flow meter’s next generation design supported this requirement. The meter’s advanced sensor features multiple coils and electrodes assembled in a tube that inserts completely into the pipe to measure the full profile of the flow stream, providing exceptional accuracy even in challenging flow conditions.

The meter’s signal converter features an advanced filtering algorithm to support accuracy of ±0.5% of reading from 1 to 32 ft/s and ±1% from 0.3 to 1 ft/s. The signal converter also includes: built-in dual 4-20 mA outputs for communication flexibility, additional programmable outputs to support SCADA systems and a simplified menu structure for ease of use. These capabilities made it easy for AVWSID to connect the meter to its SCADA system without the need for programming assistance from outside contractors.

Conclusions

AVWSID is pleased with the accuracy and performance of the FPI Mag meter. Goodrich said, “The flow meter has performed as well as advertised and the install process was as easy as we were told. We have been very impressed with the whole process, from ordering to installation.”

Based on the successful results of the FPI Mag in the pilot plant application, AVWSID is considering the purchase of more FPI Mag meters for a new treatment facility that is currently being designed and built. Goodrich said, “I hope to use the FPI Mag meters in the new facility because of its accuracy, ease of installation and integration with our SCADA system."

updated November 2022