- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Industry - Reduce the Risk of Buying your Next Electromagnetic Flow Meter.

Reduce the Risk of Buying your Next Electromagnetic Flow Meter.

When choosing an electromagnetic flow meter, it’s important to consider a selection process that will provide the best possible solution for your flow meter application.

Electromagnetic flow meters are typically the meter of choice when considering cost, accuracy and the lifetime cost of your equipment. Here are some tips that can assist with ensuring that the electromagnetic flow meter is the right choice:

Electromagnetic flow meters are typically the meter of choice when considering cost, accuracy and the lifetime cost of your equipment. Here are some tips that can assist with ensuring that the electromagnetic flow meter is the right choice:

1. Cost

How much do you want to spend? Typically when choosing a flow meter, the higher the accuracy, the higher the cost. So, when considering an electromagnetic flow meter, cost and accuracy go hand in hand. Over the years the electromagnetic flow meter offers a very high accuracy with a very reasonable cost. Your return on investment (ROI) is typically less than six months, and the accuracy achieved can be as high as .25% to .5% of flow rate. Considered one of the best choices when it comes to flow metering, this type of meter can be applied in a wide range of applications.

Since electromagnetic flow meters have no moving parts, maintenance is typically very minimal: expected service life is 30 years. Depending on your fluid media and/or water quality, the electrodes may need to be periodically cleaned according to the manufacturer’s recommendations. As you compare different electromagnetic flow meters, be sure to calculate the cost of installation and maintenance, and also amortize the cost of the flow meter over its lifespan.

Since electromagnetic flow meters have no moving parts, maintenance is typically very minimal: expected service life is 30 years. Depending on your fluid media and/or water quality, the electrodes may need to be periodically cleaned according to the manufacturer’s recommendations. As you compare different electromagnetic flow meters, be sure to calculate the cost of installation and maintenance, and also amortize the cost of the flow meter over its lifespan.

2. Application

Understanding your application consists of knowing the fluid media, media temperature, flow range, and pressure. All electromagnetic flow meters work with conductive liquids only. Flow of compressible fluids (gasses) cannot be measured with electromagnetic flow meters. Whether the fluid media is drinking water or wastewater, the type of electromagnetic meter that would work best for the application can vary based on electrode material and/or the liner or coating of the sensor that comes in contact with the media. Knowing the media being measured is only part of the understanding of the overall application. Some electromagnetic flow meters are affected by fluid temperature and operating pressure. The same electromagnetic flow meter used for a 150-psi application may not work for a 300-psi application. Most electromagnetic flow meter specification sheets indicate the specific pressure and temperature rating of the meter in question. Be sure the meter you select has specifications that will meet your application needs. What are you measuring? There are several considerations that must be known in order to apply an electromagnetic flow meter:

• Is the fluid being measured conductive? If the fluid is not conductive, an electromagnetic flow meter will not work.

• What is your line size? This will determine the cost of the meter.

• Is there proper room to install this meter? Typically an electromagnetic flow meter will have minimum upstream and downstream straight run requirements in order to measure the fluid flow accurately. Flow disturbers must be considered as well —modulating valves, chemical injection points, and anything that would compromise the fluid flow before it’s measured by the electromagnetic flow meter.

• What is the fluid being measured? Is the measured fluid corrosive? Is the measured fluid clean water or wastewater? This is important information to know when evaluating the type of lining in the electromagnetic flow meter. Common liners that are available with today’s electromagnetic flow meters are hard rubber, neoprene, Teflon, Tefzel, and ceramic. However, these types of liners do come with a risk of delamination. An electromagnetic meter with a fusion-bonded liner is recommended to avoid the possibility of delamination issues altogether.

3. Accuracy

How accurate does your measurement need to be? Electromagnetic meters, in general, are highly accurate flow meters. Most of them offer +/-.5% accuracy with no head loss. Whether using a full-bore / full pipe mag meter or an insertion mag meter, be sure the meter you choose offers precisely the accuracy needed. Accuracy for an electromagnetic flow meter is based on the percent of reading accuracy.

What is meant by the percent of reading accuracy? It is the degree of precision with which the meter can measure the indicated flow rate at that flow rate. An example of this accuracy statement is as follows: If the meter’s percent of reading accuracy is described as .5% at 100 GPM, this means that while the meter is reporting the flow rate being 100 GPM, it could actually be anywhere from 99.5 GPM (-.5%) to 100.5 GPM (+.5%).

What is meant by the percent of reading accuracy? It is the degree of precision with which the meter can measure the indicated flow rate at that flow rate. An example of this accuracy statement is as follows: If the meter’s percent of reading accuracy is described as .5% at 100 GPM, this means that while the meter is reporting the flow rate being 100 GPM, it could actually be anywhere from 99.5 GPM (-.5%) to 100.5 GPM (+.5%).

4. Upstream/Downstream Piping

What is upstream and/or downstream piping? When flow meters are placed too close to pumps, valves, elbows, and other obstructions, unstable or irregular flows can impact performance. Electromagnetic flow meters typically require minimal upstream and downstream straight run pipe. The requirements for upstream and downstream piping considerations can depend on whether the meter is part of a new piping project, a retrofit, or a line expansion. Installation requirements also vary depending on whether a full-bore mag meter or a full-profile insertion meter is chosen. Nearly all major electromagnetic flow meter technologies require a manufacturer’s specified pipe diameter straight run upstream and downstream from the meter to ensure a stable flow profile.

Failure to comply with the manufacturer’s installation requirements for upstream and downstream straight pipe run often leads to either poor accuracy or inconsistent performance. Most mag meter specification sheets indicate the upstream and downstream straight run requirements. Be sure the meter you select will fit in the spot it’s intended for.

5. Ease of Installation

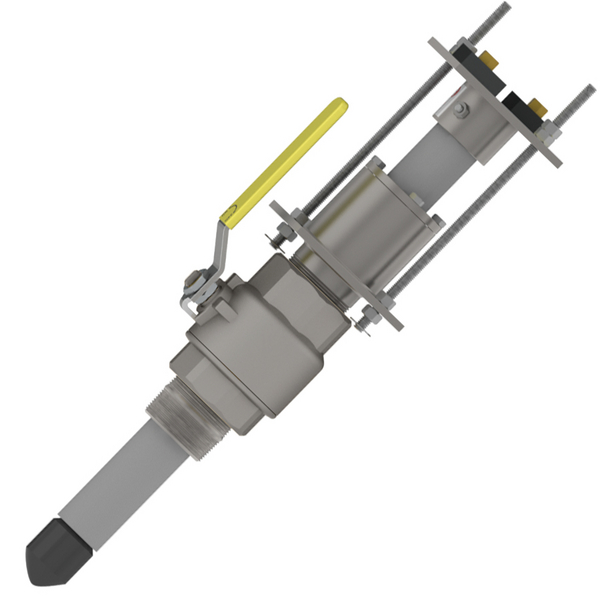

Installing an electromagnetic flow meter depends greatly on the line size, type of meter chosen, and its intended location. For smaller line sizes (12” and under), a full-bore electromagnetic flow meter may be the best choice. For larger line sizes, the heavier weight of full-bore meters typically requires the use of a crane, along with the necessary extra personnel, working space, and installation time. A full-profile insertion meter, on the other hand, can provide an economical exception to costly installation on larger line sizes. While some meters require installers to shut the line down to install flanges to accept a traditional full-bore type flow meter, a full-profile insertion meter can be installed via hot tap while under pressure, thus avoiding taking the line out of service.

What mag meter solutions does McCrometer offer for Industrial and Municipal Flow Applications?

Learn More

If you’re interested in reducing risk and installation costs of your next mag meter, need to replace a full-pipe meter with or without stopping water flow, or just want more information click here to learn more about McCrometer’s Electromagnetic Flow Meters.