- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Flow Meters for Fire Protection Agencies

Flow Meters for Fire Protection Agencies

The Crucial Role of Flow Measurement in Ensuring Safe and Compliant Fire Hydrants

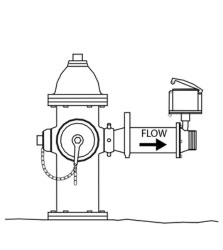

Fire hydrant flow meters are critical for validating hydrant water flow during non-firefighting operations, ensuring adequate water supply and preventing overloading during critical firefighting operations. The time to find out there is an issue is not during an emergency. The National Fire Protection Association requires fire hydrants to provide a specific flow capacity, defined as a water supply measured at 20 PSI residual pressure available for manual firefighting. The fire code NFPA 291 requires fire hydrant flow tests every 5 years and annual inspection by city officials or professional contractors.

Accurate and reliable flow measurement devices not only keep hydrants in compliance with the fire code, but can also help identify issues such as leaks, blockages, and inefficiencies, improving system performance and reducing costs. Choosing the right flow meter can make hydrant testing easy and provide trusted flow data.

Consider this:

Consider this:

Why invest in a hydrant propeller meter?

1. Simpler and more accurate than pitot gauges

Field personnel and city contractors who use pitot gauges are required to manually interact with the meter during measurement to gain a reading. The downfalls of this measurement device often lie with user error; measurement of the inside nozzle diameter, manual back-to-back readings of residual pressure, and physically holding the pitot tube all have the potential for human error.

Choosing a propeller meter streamlines the entire measurement process. Installation is incredibly simple and secure, and the flow meter provides a totalizer flow in gallons per minute without the need for calculation. Additionally, pitot tubes only measures flow velocity at one point within the flow stream, potentially producing an inaccurate reading due to velocity profile changes.

2. Durable and transportable

While pitot tubes can be hot-tapped, it’s often the grooved end or clamp-on propeller meter that is chosen for its durability and quick installation. Constructed of epoxy-coated carbon steel or even stainless-steel, the Mc ®Propeller features a high-temperature polymer impeller. Nonetheless, the meter is lightweight and portable, featuring carrying handles for easy transportation. Stator vanes located in the inlet of the flow tube generate steady, non-rotational water flow for greater accuracy.

3. Data output options

The hydrant McPropeller offers 3 registers, two of which offer output options such as 4-20mA or pulse, and ability to integrate additional sensors such as pressure and temperature. For additional data recording, the FlowConnect™ telemetry unit offers real-time data monitoring through a web application, providing data tools that can analyze flow rate, consumption, and possible anomalies.

McCrometer Fire Protection Agency Flow Meter Suite of Products

Propeller Flow Meters

McCrometer’s propeller meters are the economical choice for water flow measurement.

Propeller Meters for Direct Hydrant Connection

Propeller Meters for Additional Hydrant Application

Mc®Propeller MW500

- Available with mechanical register, digital FlowCom™, and FlowConnect™ telemetry unit

- Instantaneous flowrate indicator

- 150PSI, ±2% accuracy, ±1% over reduced range

- Top-plate design available independently of the flow tube

- 4” – 48” line sizes available

Mc®Propeller MG100

- Available with mechanical register, digital FlowCom™, and FlowConnect™ telemetry unit

- Instantaneous flowrate indicator

- 150PSI, ±2% accuracy, ±1% over reduced range

- Fixed ell design with grooved ends

- 2” – 24” line sizes available

- Custom lay lengths available

Mc®Propeller MT100

- Available with mechanical register, digital FlowCom™, and FlowConnect™ telemetry unit

- Instantaneous flowrate indicator

- 150PSI, ±2% accuracy, ±1% over reduced range

- Fixed ell design with threaded ends

- 2” – 6” line sizes available

- Custom lay lengths available

Propeller Meters Designed for Water Flow Measurement

Designed for Easy Transportation and Installation

Threaded or grooved ends compatible with grooved couplings, handles, and a lightweight stainless-steel construction makes the McPropeller M1100 a popular choice for users on the go! McCrometer understands that when city personnel and contractors need to efficiently test a fire hydrant and don’t have the time to fuss with complex installations or meters that cannot handle frequent transportation in the back of a truck.

Stator vanes located in the inlet of the flow tube generate steady, non-rotational water flow for greater accuracy. The swivel race and outlet threads are stainless steel for trouble-free hook up. If ease of use and accurate flow data is the goal, the M1100 McPropeller delivers. Eliminate the potential for human error and get the data you need to meet regulatory requirements!

How to Choose a Register?

McCrometer’s propeller flow meters are accompanied by either a mechanical register, digital FlowCom™ register, or FlowConnect™ telemetry unit. If you’re wondering what option is best for your flow application, consider this question: what caliber of data output and automation works for you?

If manually reading and recording the flow rate and totalizer data isn’t a problem, then a mechanical register will suit your needs just fine. If receiving flow data via pulse or 4-20mA signal provides more convenience and automation to your daily processes, the FlowCom™ digital register is highly beneficial. For the utmost in automated data collection, the FlowConnect™ telemetry unit eliminates manual meter reading and transmits readings to a cloud database, which you can view on a PC or cell phone.

Request Info

Further Reading

Check out the variety of information available about the McPropeller product suite.