- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Flow Measurement Challenges and Solutions

By Brad Buecker

Water is utilized for multiple purposes — cooling, process applications, service water — at many industrial plants. Accurately measuring flow rates in various process streams is critical to ensure proper equipment operation and to maximize plant efficiency. However, such measurements are often very challenging. This article outlines several examples from the power industry, and provides information regarding new technologies that address these issues.

A number of factors can substantially influence flow measurement. These include:

- Flow volume and piping size (large volumes are often difficult to quantify)

- Lack of a long straight-run piping section

- Transient flows

- Impurities in the water

- Ability to retrofit flow meters into existing piping with minimal disruption

Consider first the measurement of high-volume flows in large piping. This is of particular importance in the power industry and in heavy industrial plants that generate power or have large process heat exchangers where cooling water piping may be several feet in diameter.

For example, a critical issue in the power industry is steam surface condenser performance, in which the condenser, as its name implies, converts turbine exhaust steam into condensate for return to the boiler. This process improves the thermodynamic efficiency of the Rankine cycle by nearly one-third over what it would be if the steam were not condensed.

Cooling water flow rates of 200,000 gpm or greater at large fossil plants are not uncommon. But for a long time, flow measurements were not reliable. Thus, for condenser performance the plant’s technical monitoring personnel had to rely on the design pump curves, even though the pumps may have been in place for decades.

Age and wear typically degrade pump performance, so not only were the condenser performance calculations probably skewed but plant thermal efficiency was lowered due to reduced cooling water flow. Accurate flow measurements are necessary for timely pump repair and replacement to maintain proper heat exchanger efficiency.

A solution to this problem is technology that utilizes the property of electromagnetic flow induction, per principles first developed in the 19th century by the towering experimental physicist and chemist Michael Faraday.

Electromagnetic coils installed inside of the sensor produce magnetic fields that are influenced by flowing water. Stainless steel electrode pairs on the outside of the sensor collect the induced voltage generated by the water flow. Each voltage signal is transmitted to a converter that calculates an average flow velocity. The converter then multiplies this average velocity by the pipe cross-sectional area to produce a volumetric flow rate.

The design and mode of operation of the instrument shown in Figure 1 offer several distinct advantages, including that it does not require a long straight run of pipe either upstream or downstream — an issue that is often a bane with other flow meters. Secondly, the instrument can be hot-tapped into existing piping, such that an equipment shutdown or unit outage is not necessary for installation. Thirdly, the instrument is enclosed in a high-strength, stainless-steel body for structural integrity. And, as is typical with most modern instrumentation nowadays, the instrument signals can be directly transmitted to the plant’s distributed control system (DCS) for a continuous display of real-time data, and also for direct incorporation into heat exchanger efficiency algorithms.

Accurate cooling water flow measurements are important to detect process upsets. A case in point is sudden failure in a steam surface condenser shell that allows excess air to enter the condenser. These failures may occur without warning, whereupon the excess air coats condenser tubes and dramatically reduces heat transfer.1 Cooling water flow rates are a key component of performance monitoring programs.

Another cooling water issue, indeed an issue with industrial plant wastewater discharge in general, is emerging in which mag flow meter technology can be of great value. Permits for many new plants are becoming increasingly restrictive with regard to makeup consumption and discharge quality, and often quantity. These factors must be considered for cooling tower operation.

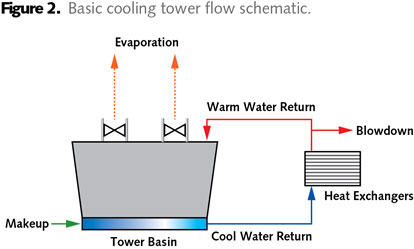

The majority of heat transfer in a cooling tower occurs due to evaporation of a small portion of the circulating water. But evaporation increases the dissolved solids concentration in the circulating water, which, even with the best chemistry treatment, will cause some constituents to reach the saturation level and begin forming scale. Thus, either periodically or continuously, some water must be blown down to keep the solids concentration below a certain limit. The level of solids in the circulating water as compared to the makeup is known as the cycles of concentration and may range from near 1 (for towers with seawater as makeup) to perhaps higher than 10 (for towers in arid locations).

While the mathematics to precisely calculate overall cooling tower water and heat balances can be somewhat complex, the relationship of blowdown (BD), evaporation (E), and cycles of concentration (COC) is outlined in the following fundamental equation:

BD = E/(COC – 1)

As is evident, increasing the cycles of concentration in the cooling tower lowers the blowdown rate, thus reducing consumption (although evaporation is usually by far the largest consumer in a cooling tower2) and discharge volume. But, higher tower cycles of concentration increase the dissolved solids concentration in the blowdown, which then may run up against discharge regulations. Precise monitoring of both makeup and discharge flow rates may be necessary to operate the tower within the required chemistry parameters, and at the same time comply with permit guidelines.

Closed cooling water is yet another cooling water application that can benefit from accurate flow measurement, if not via mag meters, perhaps with a V-Cone® instrument or some other insertion-type meter. Many plants have numerous auxiliary heat exchangers that are part of closed cooling water systems. While chemical treatment of closed cooling water is often more straightforward than open systems, that is not a license for ignoring flow data. Gradual loss of flow due to pump wear and aging will result in decreased heat exchanger efficiency. This in turn can place auxiliary systems in peril. For example, many closed heat exchangers cool lubricating oil for rotating machinery. Degradation of cooling water flow results in higher oil temperatures that, in turn, can increase the damage risk to expensive and critical equipment.

A common heat exchanger design for closed cooling water systems is the plate-and-frame type. Such exchangers provide a large surface area between plates to maximize heat transfer, but the close spacing offers many locations for fouling and flow restriction. Accurate process monitoring, including flow and temperature measurements, is necessary to maintain reliable equipment performance.

Also in this regard, numerous industrial plants rely on steam for multiple applications. Monitoring and regulation of steam flow to process heat exchangers is critical for proper equipment operation and safety. And again, as industrial processes become more automated, precise measurements can be incorporated into algorithms and computer programs that allow finely-tuned adjustments to process flows.

Another important but often-overlooked industrial measurement is that of service water flow. Of course, technologies such as mag meters can be quite effective for the large flows at municipal water treatment and wastewater treatment plants, but service water monitoring at individual industrial facilities should not be neglected. Much water may be lost at the plant due to decaying infrastructure or from other issues that cause a failure or failures in the service water system. I recently worked with a company that was losing several million gallons of water per month due to a failure in a service water system main. The leak was in underground piping near a river, and visually was difficult to detect. Only flow data indicated that a problem existed.

Conclusion

Cutting-edge technology has greatly improved the ability of personnel at a wide variety of industrial facilities to monitor process flows. This article touched upon some of the most critical applications with regard to cooling and process water measurements — measurements that are valuable for establishing and maintaining plant reliability and efficiency.

References

- Buecker, B. “Condenser Chemistry and Performance Monitoring: A Critical Necessity for Reliable Steam Plant Operation”; Paper presented at the 60th Annual International Water Conference, October 18-20, 1999, Pittsburgh, Pa.

- Buecker, B. “Cooling Tower Heat Transfer 101”; Power Engineering, July 2010.

About the Author: Brad Buecker is senior technical publicist with ChemTreat. He has 35 years of experience in or affiliated with the power industry, much of it in steam generation chemistry, water treatment, air quality control, and results engineering positions with City Water, Light & Power (Springfield, Ill.) and Kansas City Power & Light Company’s La Cygne, Ks. station. He also spent two years as acting water/wastewater supervisor at a chemical plant. Most recently he was a technical specialist with Kiewit Engineering Group Inc. Buecker has a B.S. in chemistry from Iowa State University with additional course work in fluid mechanics, energy and materials balances, and advanced inorganic chemistry. He is a member of the ACS, AIChE, ASME, NACE, the Electric Utility Chemistry Workshop planning committee, and the Power-Gen planning committee.