- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Affordable Accuracy For Water Distribution Monitoring

Non-revenue water (NRW) and other information gaps that have significant impact on operating costs are causing many water distribution utilities to seek affordable ways to gain greater insight into flow data. In this Q&A, Barry Spiegel, Director of Sales and Strategic Accounts for McCrometer, describes how full-profile insertion (FPI) electromagnetic flow meters (mag meters) can provide relief, without breaking the bank.

Every product design has its own niche. What are the strong points of FPI mag meters?

The cost and convenience of achieving accuracy in new or retrofit installations are the two greatest advantages of the FPI mag meter design. Although there are additional advantages, the key drivers typically relate to the ability to deliver quick, affordable installation in existing infrastructure and to maintain accurate measurement even in tightly spaced configurations.

What are the main advantages of the FPI mag meter design with respect to accuracy?

The need for accuracy is typically driven by how the system operator is going to use the data. Where data is used for billing or cost management measurements, accuracy becomes extremely important.

An FPI mag meter’s unique design offers + 0.5 percent accuracy, installation convenience, and a low total cost of ownership for new capital projects, maintenance/replacement projects, and, especially, retrofit applications in piping locations that were never before metered.

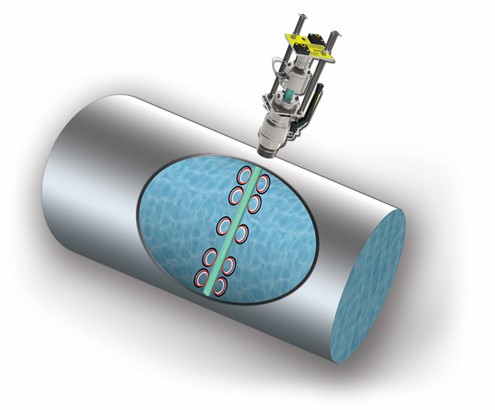

While both conventional mag meters and FPI mag meters rely on the same physics for highly accurate flow sensing — Faraday’s Law of Electromagnetic Induction — an FPI mag meter offers quicker, easier, and less costly installation options for retrofitting existing pipelines. The presence of multiple electromagnetic flow sensors along the length of the FPI mag meter probe, which spans the full diameter of the pipeline (Figure 1), ensures accurate sensing despite turbulence or irregularities in the flow profile.

Figure 1. Multiple electromagnetic fields along the length of the FPI mag meter probe sense the flow rate of water passing through the pipeline, providing + 0.5 percent accuracy across a wide range of flow conditions.

How does FPI mag meter design influence the cost and ease of installation?

There is a big difference between wanting the most accurate flow meter available and wanting the most accurate flow meter that’s affordable for the application. A meter’s purchase price is only a portion of its total cost of ownership, which reflects both its ability to adapt to the particulars of the application and the expenses associated with installation and operation.

Streamlined FPI mag meter installation through a hot-tapped ball valve connection contrasts dramatically with disruptive, labor-intensive, flange-mounted conventional mag meters — offering as high as 45 percent savings on the total cost, including installation.

With its compact configuration, hot-tap installation capability, and few concerns for pipeline turbulence or straight pipe length requirements, an FPI mag meter can be installed practically anywhere, to replace an older meter or support an entirely new measurement location. Delivery time for a custom-sized unit is approximately 10 to 15 days from the time of measurement, depending on the pipe diameter — from 4” to 138”. Because hot-tapping is done in advance to measure the true inner diameter of the pipe, final installation can typically be completed in as little as 20 to 60 minutes. Another long-term advantage of FPI mag meter hot-tap installation is that it can easily be removed for periodic cleaning or recalibration.

By contrast, mag meters with flanged connections require shutting down the pipeline for installation, cleaning, or recalibration. Also, meters of that style grow larger and heavier as the pipeline diameter increases. The larger meters extend the time and complexity of the installation process, with greater expenses for pipefitting personnel and heavy-lifting equipment.

Where are FPI mag meters most frequently used?

The FPI mag-meter design is ideal for creating new district metered areas (DMAs) to monitor distribution system NRW losses, for monitoring interconnect transfers between adjoining distribution systems, or any other potable water application where monitoring every billable drop is extremely important. Some FPI mag meters are also used to provide measurement redundancy within water treatment plants themselves. They are not recommended for use in dirty water applications that can clog the sensing electrodes spaced throughout the length of the probe.

How do FPI mag meters support the concept of DMA monitoring through wireless connections?

Smart-output FPI mag meters that can be wired to accommodate a broad range of communications networks provide plug-and-play flexibility for installation in a variety of advanced metering infrastructure (AMI) applications.

Battery-powered or solar-powered units can record measurements in remote locations, whether they are empowered for AMI data transmission or not. Those fitted with built-in transmitters as part of a larger AMI data network can provide near-real-time data to enable distribution system managers to identify potential problem areas, monitor and measure flows, and react with appropriate management interventions.

For pipeline segments where the flow can only be in one direction, a forward-flow-only FPI mag meter is sufficient. For system interconnects, DMAs with multiple entry/exit points, or pipeline segments where water can flow back and forth, a bidirectional measurement FPI mag meter is required.

Finally, are there any aspects of FPI mag meter applications where users need to pay special attention to installation or use?

Users should be aware of installation positioning options and requirements — from both the perspective of mounting clearance and mounting angle. Users need to leave sufficient clearances in the final installation to allow the full length of the probe to be withdrawn for cleaning or calibration. Fortunately, the FPI mag meter does not always need to be mounted in the top-down vertical position. It can be installed anywhere from a top-down to a horizontal insertion, just never from the bottom up. That could cause debris settling at the bottom of the pipe to foul the sensors.

A secondary consideration is proximity to chemical injection points within a treatment plant or distribution pipeline. The FPI mounting point should be at least 10’ to 15’ downstream from the chemical injection.

Barry Spiegel: Barry Spiegel has more than 20 years of experience within the municipal and industrial markets, working for Veralto companies. Most recently, Barry has spent 4 years specializing in flow meter solutions, working with customers worldwide.

Barry Spiegel: Barry Spiegel has more than 20 years of experience within the municipal and industrial markets, working for Veralto companies. Most recently, Barry has spent 4 years specializing in flow meter solutions, working with customers worldwide.