- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Not All Differential Pressure Meters Are Created Equal

Due to the dynamics of liquids and gases flowing through elbows, valves, pumps, and other pipeline structures, every flow-meter methodology has its own design limitations. Unlike Venturi meters, pitot tubes, orifice plates, and other devices, V-Cone meters provide highly accurate and reliable readings with minimal straight-pipe length restrictions and virtually no maintenance, in pipe sizes up to 120”.

How V-Cone Measurement Works

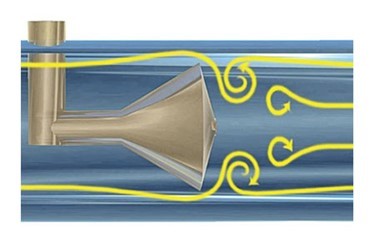

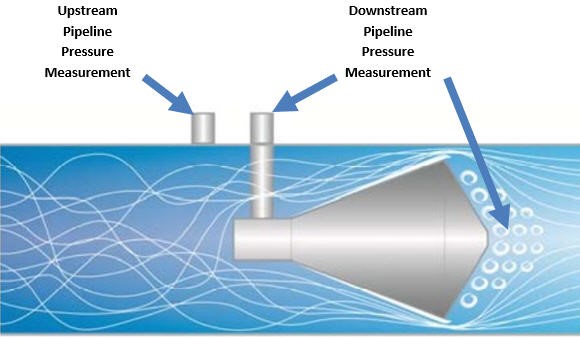

Like other flow measurement devices based on the Bernoulli principle, which defines the relationship between the velocity of a fluid and the pressure of a fluid, the V-Cone design measures the differential between the pressure in the full bore of the pipe vs. the pressure after the constriction (Figure 1). It provides near-instantaneous response time to pressure changes, across a wide range of flow velocities and flow characteristics — velocity, gas/liquid composition, particulate matter, etc. Best of all, the V-Cone delivers those benefits without many of the limitations inherent in other Bernoulli-principle designs — i.e., Venturi tubes, orifice plates, etc.

Because a V-Cone functions as its own flow conditioner, it is not bothered by turbulence in the incoming flow, regardless of the medium (gas or liquid) or the length of straight pipe leading to the meter. In flows with gas bubbles entrained in the liquid, the V-Cone breaks large bubbles into a well-dispersed stream of fine bubbles for less disruption in the measurement. Even in gas flows with small solid or liquid particles representing up to 10 percent of the total flow — such as steam/condensate flows or the outputs of oil/gas separators — the V-Cone design provides robust performance with peak accuracy.

The Advantages Of V-Cone Technology In Pipelines Large And Small

As pipeline sizes increase, the number of technology options for reliable metering of liquid, steam, or gas media becomes more limited. Compared to other metering technologies, V-Cone technology incorporates a variety of design features to deliver benefits of installation and maintenance convenience plus reading accuracy for both new and retrofit applications — in pipe sizes from 0.5” to 120”:

- High Accuracy And Repeatability. In gas and liquid measurement, the V-Cone design is rated for + 0.5-percent accuracy with repeatability of + 0.1 percent, even in the face of challenging applications.

- Minimal Straight-Pipe Length Requirements. Because the V-Cone design provides a smooth flow profile through the measurement zone, it cuts upstream straight-pipe length requirements to 1x or 3x pipe diameters (d), and downstream requirements to just 1d without compromising accuracy. That reduces the cost of associated piping and structural support. By comparison, Venturi meters and orifice plates can require 15d upstream for water and 24d or more upstream for gas. If that pipeline space is simply not available, users must choose to redefine their accuracy expectations or reduce the reliability of their readings according to published standard-rating charts.

- Small Footprint. Not only does a V-Cone meter fit in its own compact space, it also significantly reduces the footprint for piping leading up to and away from the meter, without affecting accuracy. That is a cost-saving benefit in terms of piping and support requirements for any application, but it is particularly attractive for satisfying limited space applications in pump stations and for reducing both critical space and weight demands in platform-mounted applications.

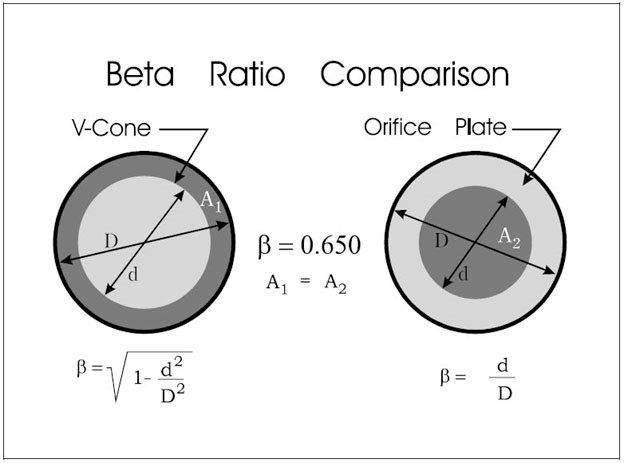

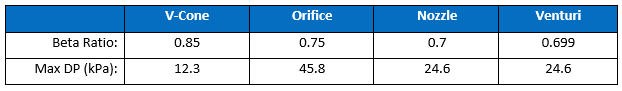

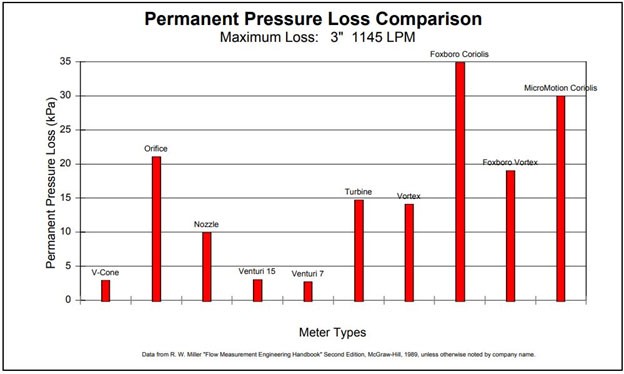

- Low Permanent Pressure-Loss. The smooth, even transition of flow around the V-Cone restriction minimizes permanent pressure-loss. The beta ratio of a differential pressure (DP) meter (Figure 2A) is often viewed as a source of permanent pressure-loss. The V-Cone design operates at a recommended pressure differential that is only half that of other DP meters (Figure 2B); however, it performs better than other DP meters in real-world applications despite its higher beta ratio. In fact, in an analysis of 10 competitive DP meters, the V-Cone design ranked right next to the best choice for low permanent pressure-loss (Figure 3).

Figures 2A and 2B. The beta ratio of a DP meter is the ratio of the smallest open area to the largest open area in the meter (typically the diameter of the constriction to the diameter of the pipe). With a V-Cone meter, that unconstrained area is a narrow open ring around the cone, as compared to a centered hole in an orifice plate. Because a V-Cone meter works with a lower differential than other types of DP meters, it experiences low permanent pressure-loss that reduces pumping energy costs despite a higher beta ratio.

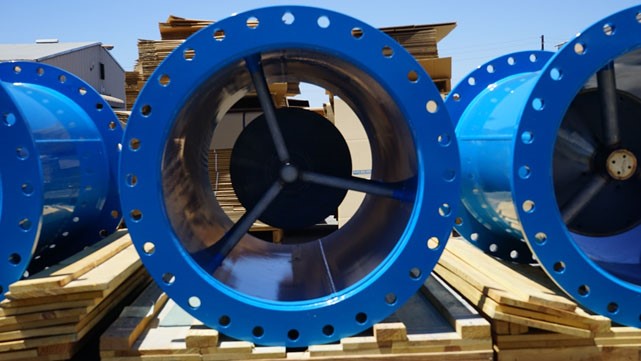

Figure 3. This chart from a pressure-loss comparison white paper shows that a V-Cone meter had the second lowest permanent pressure-loss in a rating of 10 DP meter types. - Structurally Reinforced Design. In order to deal with the stresses of turbine surges or vibration in extreme applications, a patented V-Cone design stiffens the rigidity and gusseted support on both sides of the cone’s center of gravity to withstand the more demanding applications of larger pipeline installations (Figure 4). Traditional V-Cone designs have already been executed in water piping applications up to 120” in diameter and the new reinforced designs have been proven in gas and oil pipeline applications up to 70” so far.

Figure 4. V-Cone meters designed specifically for the heavier demands of larger and more stressful installations incorporate a gusseted mounting design for the cone to protect against vibration and surges. - Superior Turndown Range. V-Cone meters routinely handle flow turndowns in excess of 10:1 and in some cases as high as 35:1. This compares to a limited 3:1 or 4:1 turndown for Venturi meters or orifice plates. This is a great advantage in applications involving steam or saturated steam, which might otherwise need two parallel lines to accommodate both high-flow and low-flow rates.

- Customizable Design. Key aspects of V-Cone design can be customized in terms of sizing the primary element to meet the sweet spot of customer requirements for turndown, total pressure loss, or even sizing the valve to the range of operability for the specific pressure-differential transmitter being used.

- Maintenance-Free. No Recalibration. With no movable parts, the V-Cone design has no need for recalibration and no wearable parts to require maintenance. This is a tremendous advantage over the maintenance requirements of orifice-plate or ultrasonic meter designs.

- No Electrical Interference. Whereas full-bore electromagnetic meters can be influenced by electrical signal noise in crowded industrial or utility environments, there is no electronic interference on the differential pressure reading generated by a V-Cone meter.

- A Reliable Retrofit Solution. Because a V-Cone meter reduces piping requirements leading to the meter — minimizing both space and weight concerns without compromising accuracy — it is an easy-to-install replacement for cramped installations and those currently suffering from compromised accuracy.

- Lower Total Cost Of Ownership (TCO). For new large-diameter pipe installations, facilities can use V-Cone meters to maximize both direct and indirect cost savings. They are more affordable than full-bore electromagnetic meters and provide economies of design that apply across multiple aspects of reduced piping requirements, reduced maintenance, and broad turndown ratios.

See Accurate Readings Across A Variety Of Conditions

Although most metering technologies tend to have strengths and weaknesses in different operating environments, V-Cone meters deliver a happy medium of accuracy, versatility, and installation flexibility across a wide range of applications:

- Raw Water Flow. V-Cone characteristics accommodate raw-water applications faced with widely variable flow rates, even when accompanied by particulate matter in the flow. In a well-water application with historic wear and accuracy problems among its mechanical meters due to turbulence, short pipe runs, and sand/debris in the flow, a V-Cone design with no moving parts satisfied all of those concerns in the limited piping space available. In one reservoir raw-water measurement application, a V-Cone meter replaced a flow tube that varied widely in accuracy from 5 percent at the low flow rate of 5 MGD up to 35 percent of the high flow rate at 45 MGD. The V-Cone meter delivered + 2-percent accuracy across the entirety of the highly variable flow range.

- Output From Oil/Gas Separators. Well streams that exceed the capacity of a test separator tank can carry contaminants that compromise the performance of orifice plates or turbine meters due to wax/asphaltine buiIdup, sand/cavitation erosion, or grease deposition from upstream valve lubrication. The V-Cone design avoids those problems. It also eliminates the need for orifice plate changes to cope with turndown requirements as dominant flow velocities change over time.

- Steam/Saturated Steam/Condensate. V-Cone meters can also handle the irregularities of steam in its various forms and applications — even saturated steam, which is non-homogenous and subject to cavitation, shocks, and other irregularities.

- Liquid-Entrained Gases. In wastewater treatment, an example of a liquid-entrained gas would be digester gas flowing to a power generation boiler. In oil and gas applications, a common V-Cone meter use is in measuring flow at the outlet of an oil-gas separator. Such an installation can be configured to sound an alarm when water content rises above a certain level as detected by changes among multiple sensing locations.

- Low-Pressure, High-Velocity Gas. A low-pressure gas flowing to a gas scrubber requires turndown ability to provide stability of the reading signal throughout a range of flow velocities. The signal from an orifice plate is too erratic and the range is too limited due to the abrupt geometry of the design.

- Aggressive Environments. The ability to customize V-Cone construction in a variety of stainless steel, duplex stainless steel, Hastelloy, Inconel, and titanium materials enhances the ability to deliver the benefits of V-Cone performance in applications ranging from water desalination plants to aggressive subsea oil and gas environments.