Article | January 31, 2023

Download as a PDF document

Electromagnetic flow meters (also called mag meters, electromag meters or magnetic flow meters), are volumetric flow meters that use electromagnetic induction to measure liquid velocity. This method of measurement is highly accurate at measuring water-based fluids as they pass through a pipe.

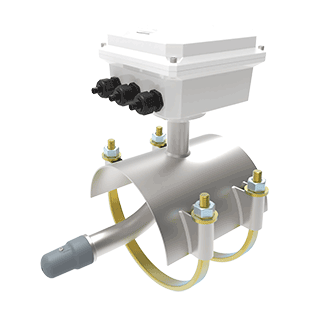

Electromagnetic flow meters feature an obstruction-free design which eliminates flow impediment and operate with electrodes embedded on opposite sides of the flow tube or sensor to pick up the signal. Mag meters perform extremely well in many municipal and processing applications and have become the meter of choice for measuring conductive liquids such as water or slurry.

Finally, mag meters do not have any moving parts, so there is minimal need for maintenance or replacement. Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better.

Electromagnetic flow meters (also called mag meters or magnetic flow meters), are volumetric flow meters that use electromagnetic induction to measure liquid velocity.

Electromagnetic flow meters (also called mag meters or magnetic flow meters), are volumetric flow meters that use electromagnetic induction to measure liquid velocity.

This method of measurement is highly accurate at measuring water-based fluids as they pass through a pipe.

Mag flow meters do not have any moving parts, so there is minimal need for maintenance or replacement. Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better.

How Does a Mag Meter Work?

Electromagnetic flow meters use electrodes to create a magnetic field that the liquid in question flows through. Those electrodes read the water’s voltage as it passes through the field.

Mag meters operate under the principle of Faraday’s Law of Electromagnetic Induction to measure liquid velocity.

What is Faraday’s Law?

Faraday’s Law states that a conductor moving through a magnetic field produces an electric signal within the conductor, which is directly proportional to the velocity of the water moving through the field.

In essence, as fluid flows through the magnetic field, conductive particles in the fluid create changes in voltage across the magnetic field. This variation is used to measure and calculate the velocity of water flow through a pipe.

Advantages of Using Electromagnetic Flow Meters

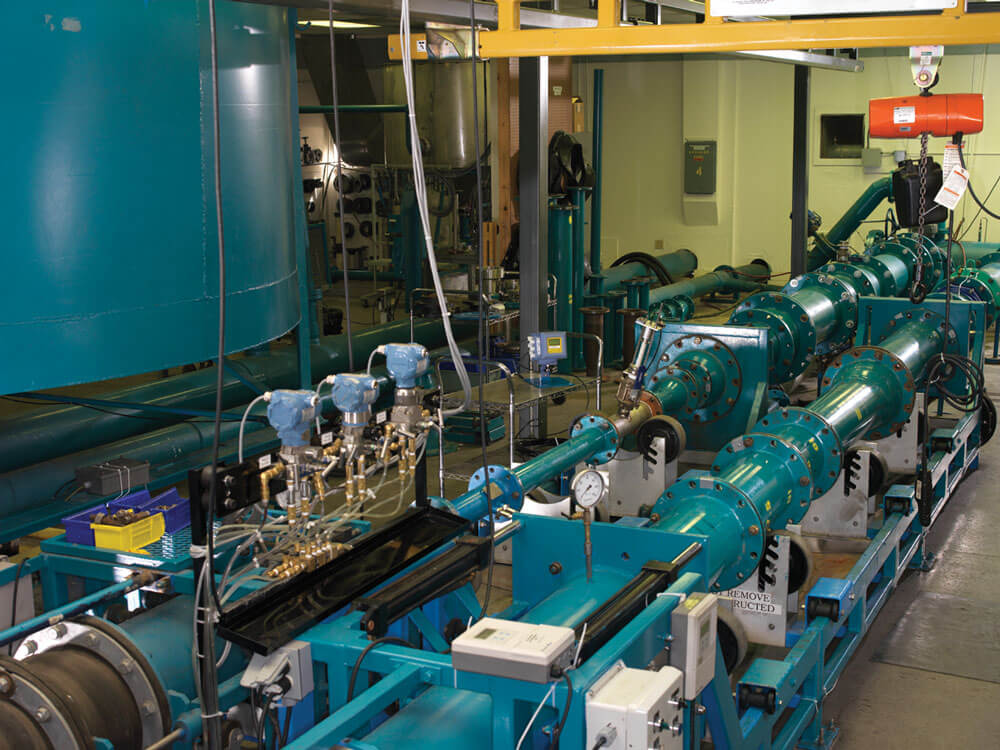

Electromagnetic (mag) flow meters are advantageous for companies in municipal, agriculture, oil and gas and other industrial applications. These meters help companies operate at their most optimal levels.

Highly Accurate

Mag meters are highly accurate when compared to other flow meters. Accuracy over a wide flow range is estimated to be ±0.5% of flow rate or better, compared to the inaccuracies of ±1 to 2 percent of rate that come with ultrasonic meters.

Accuracy is everything when measuring water-based solutions, because it leads to lower costs and high efficiency.

Cost-Effective

Mag meters are a cost-effective solution for a variety of reasons:

- By producing extremely accurate measurements, electromagnetic flow meters reduce excess cost.

Inaccurate measurements produced by other flow meters may result in more product being sold than was paid for, or conversely, too little product being sent, leading to late fees, poor reputation, and additional transport trips. - Installation is simple and straightforward. Mag meters can be retrofitted to existing systems and installed without diverting flows or shutting down systems.

- Finally, the lack of moving parts on mag meters means they require little to no maintenance. Once installed and operational, mag meters will keep measuring without any further resources spent on them.

Measure Bi-directional Flow

Bi-directional flows are not common in many industries, but for those who work with these systems, measuring flow has historically been difficult. Other types of flow meters only measure flow in one direction, so measuring bi-directional flow required two meters installed, facing opposite directions.

Bi-directional flows are not common in many industries, but for those who work with these systems, measuring flow has historically been difficult. Other types of flow meters only measure flow in one direction, so measuring bi-directional flow required two meters installed, facing opposite directions.

Mag meters’ simple design and use of magnetic fields, however, enable them to measure flow in any direction—a huge benefit for engineers specifying a flow meter to their complex process systems.

Disadvantages of using Magnetic Flow Meters

It depends on the meter itself, but some flow tube meters have a liner which can separate from the meter causing system damage and requiring maintenance. Look for a meter that does not require a liner, such as McCrometer’s Ultra Mag flanged magnetic meter with an NSF-approved, fusion-bonded epoxy liner: the UltraLiner.

Mag meters also don’t work on nonconductive fluids such as oils, steam or gas, differential pressure flow meters should be used here.

Electromagnetic Flow Meters: Common Uses</h3

Common industries that use electromagnetic flow meters include:

Common industries that use electromagnetic flow meters include:

Agriculture and irrigation

Accurate water flow measurement is crucial in agriculture and irrigation, especially when extreme or varying climates are in play.

Choosing a mag meter to measure irrigation flow is a low-maintenance option that meets industry standards and has been trusted for several decades.

Wastewater

High levels of uptime are very important when managing wastewater. Mag meters are great in this case, because maintenance and repairs are rare and installation doesn’t create significant downtime.

High-quality meters will also operate in extreme temperatures, so climate won’t cause shutdowns.

Drinking water

Cost-management is top of mind for companies dealing with drinking water. Electromag flow meters optimize flow control and cut costs by keeping readings as accurate as possible. They can also earn NSF-61 certifications, ensuring their safety for drinking water applications.

Cooling water

Cooling water is a hugely important component to the electrical, industrial, and manufacturing industries. Mag meters meet industry requirements for accuracy, and meet operators’ expectations for durability.

Industrial

Industrial applications often require tools that are durable and can withstand high pressure.

High-quality mag flow meters withstand industrial use, require minimal maintenance, and qualify for Class 1, Division 2 classifications for hazardous areas, making them a favorite among engineers in the industrial sector.

How to Choose a Mag Flow Meter

There are several considerations to keep in mind when choosing a mag flow meter:

- Cost: Mag meters come at a variety of price points, but generally, the more you spend, the better the accuracy will be. That accuracy becomes ROI over the coming years.

- Application: The type of fluid, temperature of fluid, flow range, and pressure will help determine the type of electromagnetic flow meter that will work best.

- Accuracy and range: Certain meters may offer more precision than others (full-bore mag vs. full-profile insertion). Make sure you choose a meter that offers the level of precision necessary for your business. Turndown, or flow range of the meter, is another important consideration when choosing a mag meter.

- Upstream and downstream piping: Mag meters work best when there is minimal upstream and downstream straight piping used. However, the importance varies based on whether the project is new, a retrofit, or an expansion.

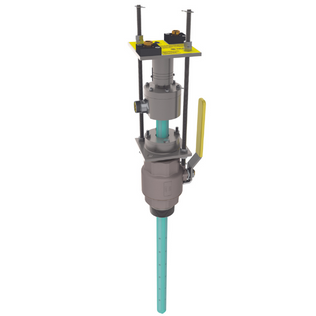

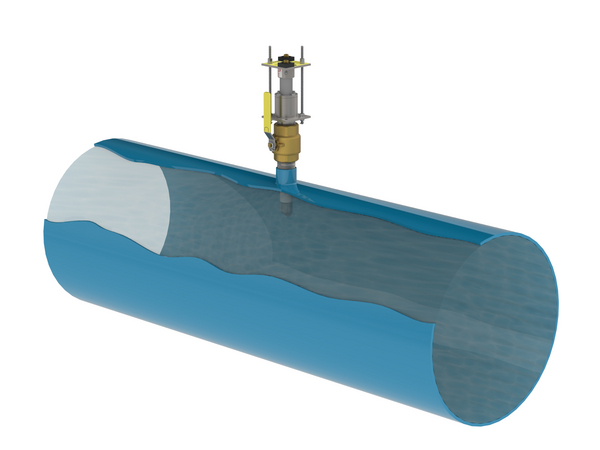

- Ease of installation: The best meter for each project will vary based on line size and location. For example, a full-bore meter may work best for smaller line sizes, while a full-profile insertion meter can be a cost-effective choice for larger projects.

Electromag Flow Meter Installation

There are a few considerations to keep in mind when installing a mag meter.

Regardless of the electromag flow meter chosen, one of the most important factors is the location chosen for the sensor. It should be an area with full flow and minimal interference. The grounding requirements discussed in the next section are also important for optimal meter insertion.

Read more about the variations in installation of different insertion-type electromagnetic flow meters. For example, in-line flow meters don’t require as much straight pipe as insertion mag meters, which require a minimum of 10 pipe diameters downstream and 5 pipe diameters upstream.

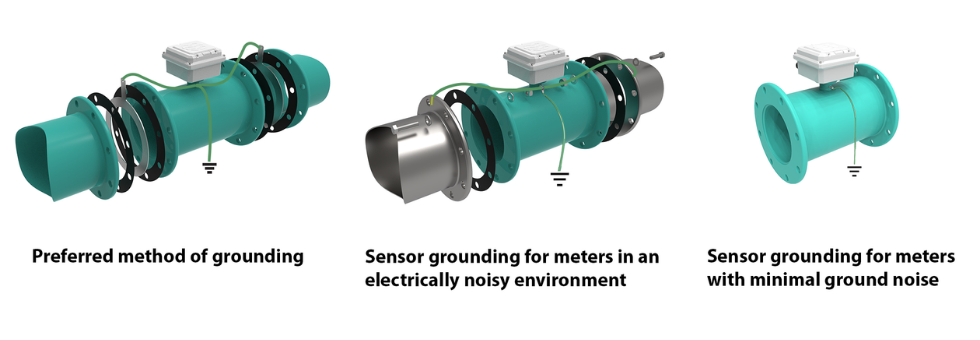

Electromag Flow Meter Grounding Requirements

Following instructions for grounding your flow meter are crucial to ensure correct readings.

This is because the liquid running through the pipes carries its own static electricity that can interfere with meter readings. Instructions may vary based on the flow meter used as well as the piping system in place.

Dura Mag Grounding Options

Challenges of Using Mag Flow Meters

Electromag flow meters offer many benefits to companies producing or managing water-based liquids. Let’s discuss some of the common challenges of using mag flow meters and how to overcome those challenges.

Separate Liner Required

One common challenge of electromagnetic meters occurs with flow tube meters that require a separate liner to be used. This liner can separate from the meter in some instances, possibly requiring maintenance. The best way to avoid this issue is to simply choose a flow meter without a separate liner. McCrometer’s Ultra Mag flanged mag meter is a great option, because it uses a fusion-bonded epoxy liner that will not separate.

Air Bubbles can Throw off Readings

Another challenge that can affect the accuracy of readings is air bubbles filling the pipe. Since mag meter sensors are highly sensitive, air bubbles can throw off the readings. This issue can be avoided by making sure water fills the pipe completely. Installing the sensor at the angles suggested by installation instructions will eliminate the risk of bubbles.

Keep in mind that for mag meters to measure accurately, liquids must be water-based. They will not work correctly on non-conductive fluids, including oils, steam, or gas. Unfortunately, these liquids will need to be measured with an alternative type of meter.