- PRODUCTS

- INDUSTRIES

- RESOURCES

- SUPPORT

Maximizing AMI Investments Through Broader IIoT Insight

Advanced metering infrastructure (AMI) has received a lot of attention in recent years, typically regarding customer account billing. Other AMI uses within water distribution networks, however, can play equally important roles in reducing non-revenue water (NRW). Consider these contributions of networked flow meter use for automating better insights into water distribution efficiency.

Benefits Beyond The Residential AMI Mind-set

While residential billing accuracy is a primary focus of AMI infrastructure, overlooking the cost-saving implications of distribution system monitoring is like passing up dessert after a satisfying main course. That is because highly accurate electromagnetic meters (mag meters) with built-in AMI-system compatibility can create added opportunities to rein in costs by providing water distribution data that residential meters alone cannot provide.

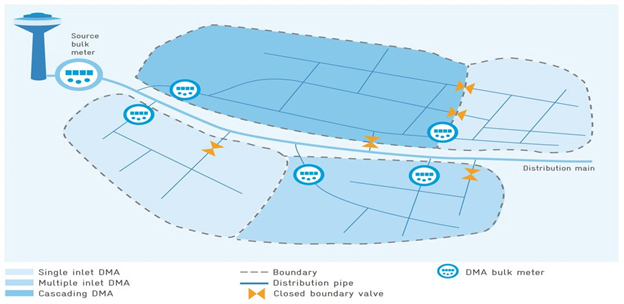

Monitoring accurate flow data from key locations throughout water distribution infrastructure provides insight into current performance and more options for improving future operating efficiency (Figure 1). The concept works for utilities large and small, enabling astute water distribution managers to identify potential problem areas and make better distribution system management decisions with minimal data collection effort.

- Better Visibility Into Physical System Performance. Monitoring flow rates with mag meters identified by GPS location, then tying those results into SCADA systems, analytical AMI software, or utility GIS mapping systems, provides convenient snapshots of overall performance. It can help pinpoint potential problems with aging water mains, new construction leaks, damaged hydrants, and more.

- Better Visibility Into Financial Performance. Confirming performance efficiency and providing better asset management insight supports improved return on investment (ROI) across the entire water distribution infrastructure.

- The Best Of Both Worlds. Only full-profile-insertion (FPI) mag meter technology meets both distinct sets of customer needs — highly accurate remote data collection with the most cost-efficient implementation.

Extend The Reach And Value Of Existing AMI To Water Distribution Management

Field-mounted mag meters transmit short bursts of recorded data at frequent intervals, the same as any other Industrial Internet of Things (IIoT) node in a networked system. Their compatibility with standard wireless transmission protocols makes it easy to collect data from remote locations with minimal logistical concerns. The battery-powered units can supply accurate readings for years without requiring hardwired power, labor-intensive data collection, or frequent battery replacement.

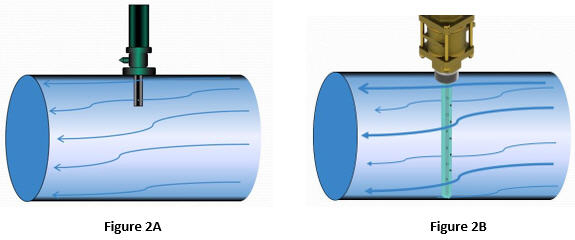

In contrast to partial-insertion mag meters, which measure flow across only a fraction of the pipeline cross section (Figure 2A), FPI mag meters calculate flow measurements at multiple locations across the full diameter of the pipeline (Figure 2B).

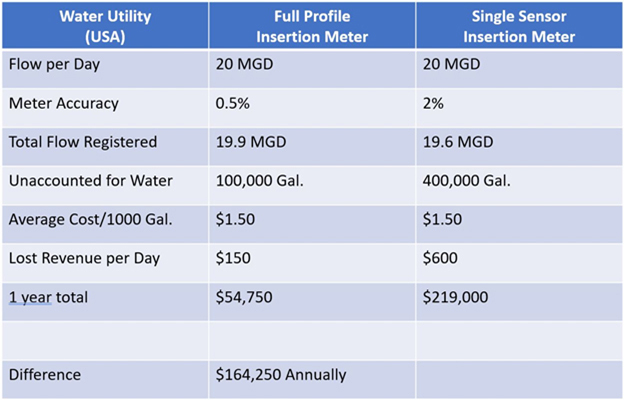

For utilities that already have AMI network infrastructure in place, adding supplemental data collection locations by using mag meters with system-agnostic operation make the process virtually transparent. Hot-tap mounting capabilities cut installation costs significantly as compared to flanged full-bore mag meters, while maintaining cost-saving flow-measurement accuracy (Figure 3). Previously installed networking and software capabilities simply absorb the new data sources into the current analytics and reporting programs where managers are free to analyze them for multiple purposes.

Anticipate Distribution Monitoring In Future AMI Planning

Even for utilities that have not yet installed AMI capabilities at individual residential account locations, it can pay to look ahead to bulk mag meters that are versatile enough to monitor larger distribution infrastructure pipelines as part of the same AMI network. For example, FPI mag meters that accept both three-wire connections as well as 4-20 mA and digital pulse outputs can work with most AMI networks.

Stay Up To Date On Clean-Water Flow — Coming And Going

Whatever the metering requirements, FPI mag meters installed in water intake or distribution pipelines provide highly accurate (+ 0.5-percent) readings in any water flows with low turbidity and particulate matter. In water treatment and distribution, these applications include:

- Recording source-water intakes to document rationed source-water allotments.

- Monitoring in-plant flow readings to allow for better chemical dosing accuracy.

- Documenting distribution system flows for locating and minimizing NRW flows and for improving overall management decision-making.

For drinking water utilities, the advantages of AMI supported by FPI mag meters within the water distribution network address a wide variety of management concerns:

- District Metering Areas (DMAs). Monitoring DMAs allows water utilities to track and control specific service zones independently. This makes it easier to identify flow trends that might indicate potential problems.

- Day-Part Monitoring. Every water distribution system experiences varying demands based on diurnal patterns of use. Tracking flow and pressure, zone by zone, against billed consumption makes it easier to identify patterns of exceptional water use or water loss. It can also indicate areas of heavily scaled water main infrastructure that no longer offers sufficient capacity to satisfy normal water needs at normal pressures.

- NRW Losses. Making it easier to monitor and record flow patterns vs. consumption patterns cross-referenced from many combinations of transmission network and customer locations makes it easier to pinpoint actual and apparent water losses.

- Leak Detection. Monitoring late-night flows, when consumption is normally at its lowest, can help to identify areas of abnormally high flows that might indicate potential leaks.

- Convenient Maintenance And Calibration. The ability to remove an FPI mag meter from a pressurized pipeline and immediately replace it with a spare — without disrupting water service — makes it easy and inexpensive to meet planned or regulated calibration and cleaning.

Learn More About Task-Specific Mag Meter Advantages

Water utility managers and engineers interested in a more detailed understanding of the physical characteristics and benefits of FPI mag meter implementation in water distribution can click to this article on sizing, selection, and installation/mounting flexibility.